Timber

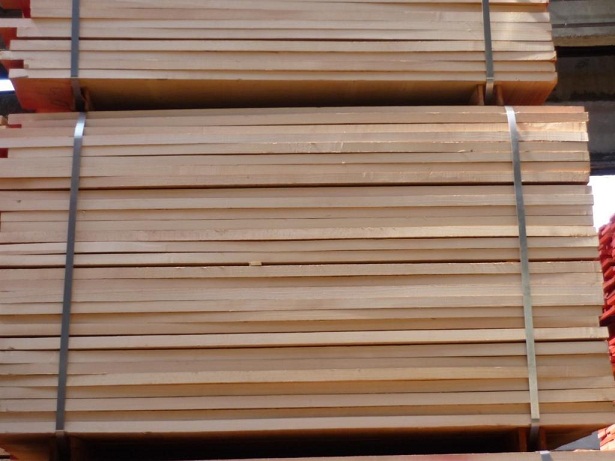

(beech timber)

Fagus sylvatica L., or European beech, is one of the most important and widespread broadleaved trees in Europe, being a hardy species. In contrast to many other tree species, it is able to maintain a high rate of growth until a relatively mature age. Though not demanding of soil type, beech requires a humid atmosphere with precipitation well distributed throughout the year and a well-drained soil. It tolerates rigorous winter cold, but is sensitive to spring frost. Owing to the capacity of its root system for assisting in the circulation of air throughout the soil, and the amount of potash in its leaves, Beech trees conserve the productive capacity of the soil better than many other species

With around 250 known usages, it is one of the most diversely used tree species in Europe. Its wear-resistance, strength and excellent bending capabilities make it ideal for boatbuilding, flooring, stairs, furniture, musical instruments (piano pin blocks), plywood, panels, veneering and cooking utensils such as bowls, platters and wooden spoons. It is also used for pulp and can be coppiced for fire wood and charcoal due to its relatively high energetic potential, considered one of the best firewoods for fireplaces, Its wood is strong, light-colored and can be machined easily making it ideal for a wide range of uses, Its tight, fine grain gives it an excellent finish and wood stain is absorbed quickly.

Its fine and short grain makes it also an easy wood to work with, easy to soak, dye, varnish and glue. Steaming makes the wood even easier to machine. It has an excellent finish and is resistant to compression and splitting and it is stiff when flexed.

Milling is sometimes difficult due to cracking. The density of the wood is 720 kg per cubic meter. It is particularly well suited for minor carpentry, particularly furniture. From chairs to parquetry (flooring) and staircases, the European beech can do almost anything other than heavy structural support, so long as it is not left outdoors. Its hardness make it ideal for making wooden mallets and workbench tops. The wood rots easily if it is not protected. It is better for paper pulp than many other broadleaved trees though is only sometimes used for this, the high cellulose content can also be spun into modal, which is used as a textile akin to cotton.

A Grade

SQUARE EDGED BEECH TIMBER, LIGHTLY STEAMED, KD 10-12%, 4 FACES CLEAR over 95%, BUNDLES SANDED ON SIDES

A Grade Assortments:

– Thickness: 25, 32, 38, 50, mm;

– Long 2 (TAL 2): 2.10 m and longer; 10 cm and wider;

– Long 1 (TAL 1): 1.70–2.00 m; 10 cm and wider;

– Long narrow (TAL ingust): 1.70 m and longer; widths 7, 8, 9 cm;

– Short (TAS): 1.00-1.60 m; 10 cm and wider;

– Supershort (TASS): 0.30-0.90 m; 8 cm and wider – 1 length/bundle;

– Supershort narrow (TASS ing): 0.45-0.90 m; widths 5,6,7 cm.

Wood Processing details

– KILN DRIED 10-12% (+/-2%) (22 drying kilns)

– Packing: 1 length / bundle (including for supershort)

– Light steaming: 8 Hours (4 steaming rooms)

– Uniform color

– Antiseptic treated

– shipping marks and painted on ends (on request)

– squared 4 sides

– Oversize in length, width, thickness

Product Gallery

Our products are appreciated worldwide, we guarantee high standards, quality, perseverance!

AB Grade

SQUARE EDGED BEECH TIMBER, LIGHTLY STEAMED, KD 10-12%, SOUND RED HEART TOLERATED, 3&4 SIDES CLEAR, BUNDLES SANDED ON SIDES

AB Grade Assortments:>

– Thickness: 25, 32, 38, 50, 60 mm;

– Long 2 (TAL 2): 2.10 m and longer; 10 cm and wider;

– Long 1 (TAL 1): 1.70 – 2.00 m; 10 cm and wider;

– Long narrow (TAL ingust): 1.70 m and longer; widths 7, 8, 9 cm;

– Short (TAS): 1.00 – 1.60 m; 10 cm and wider;

– Supershort (TASS): 0.30 – 0.90 m; 8 cm and wider; (lengths from 10 to 10 cm and 1 length/bundle as packing)

– Supershort narrow: 0.30 – 0.90 m; widths 5, 6, 7 cm; (lengths from 10 to 10 cm)

Wood Processing details

* Markets

A Grade-orient

(Midlle East & North Africa)

SQUARE BEECH TIMBER, STEAMED, SOUND RED HEART TOLERATED, min. 3 SIDES CLEAR (with no limits for red coloration). KD 10-12% FOR THICKNESSES BETWEEN 25 AND 60 MM. KD 18-20% FOR 70&80 MM THICKNESSES

A Grade-orient Specification:

– Thickness: 25, 32, 38, 50, 60, 70, 80 mm;

– Long (TAL): 1.80 m and longer, 10 cm and wider;

– Short (TAS): 1.00 – 1.70 m, 10 cm and wider;

– Super short (TASS): 0.30 -0.90 m, 8 cm and wider (lengths from 10 to 10 cm);

– Super short narrow (TASS): 0.30-0.90 m, 5,6,7 cm (lengths from 10 to 10 cm)

Wood Processing details

– KILN DRIED 10-12%/18-20 %, +/-2% (22 drying kilns)

– Packing: 1 length / bundle (including for supershort)

– Steaming: 40-48 Hours (4 steaming rooms)

– Uniform color

– Antiseptic treated

– shipping marks and painted on ends (on request)

– squared 4 sides

– min. 3 sides clear of defects

– Oversize in length, width, thickness

* Markets

This quality is an A and addresses the Middle East and NORTH Africa markets